On a quiet Monday morning, we got the kind of call that keeps operations managers on their toes.

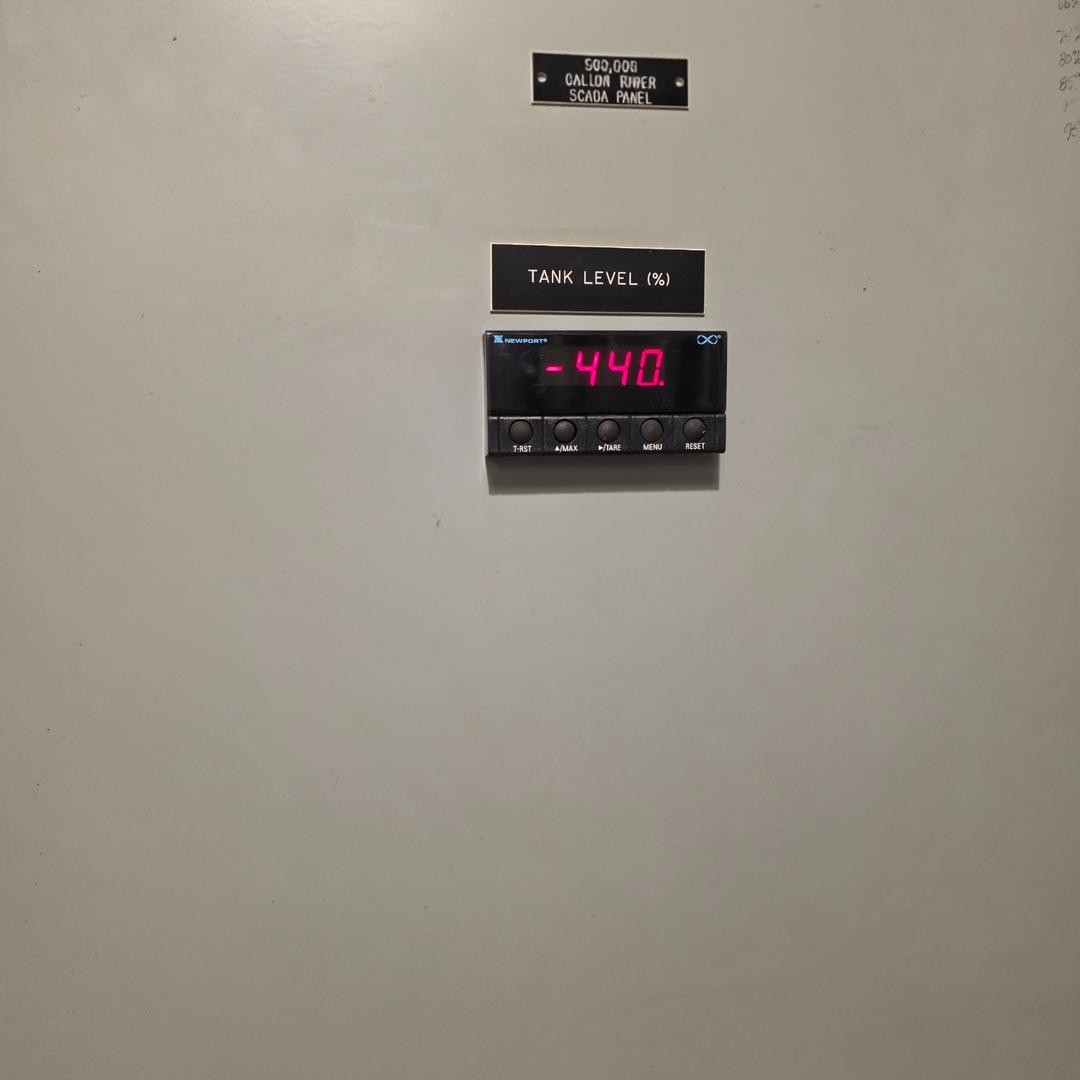

A municipal water department contacted us with an urgent issue: their water tower wasn’t responding properly to level control commands. The pressure transducer responsible for monitoring tank levels had failed a single point of failure in an otherwise smooth-running system. Without it, they were flying blind when it came to managing their water supply.

Water towers don’t wait, and neither do we.

Step One: Start the Clock

We immediately opened a service ticket and pulled up the customer’s file to collect the necessary specifications. That’s when we had a huge advantage.

Just the year before, our team had performed a full system calibration at this site. That meant we already had:

The exact make and model of the existing pressure transducer

Operating range data and pressure span

4-20 mA scaling values

Mounting orientation details

Environmental conditions the sensor was exposed to

In less than an hour, we located and ordered a compatible replacement unit. Since we already had the full calibration data, we were able to pre-calibrate the new pressure transducer in our shop before even stepping foot on-site.

This step alone likely saved us a full day of trial-and-error testing and setup, and more importantly, saved the customer from prolonged downtime.

Step Two: Site Visit, Same Week

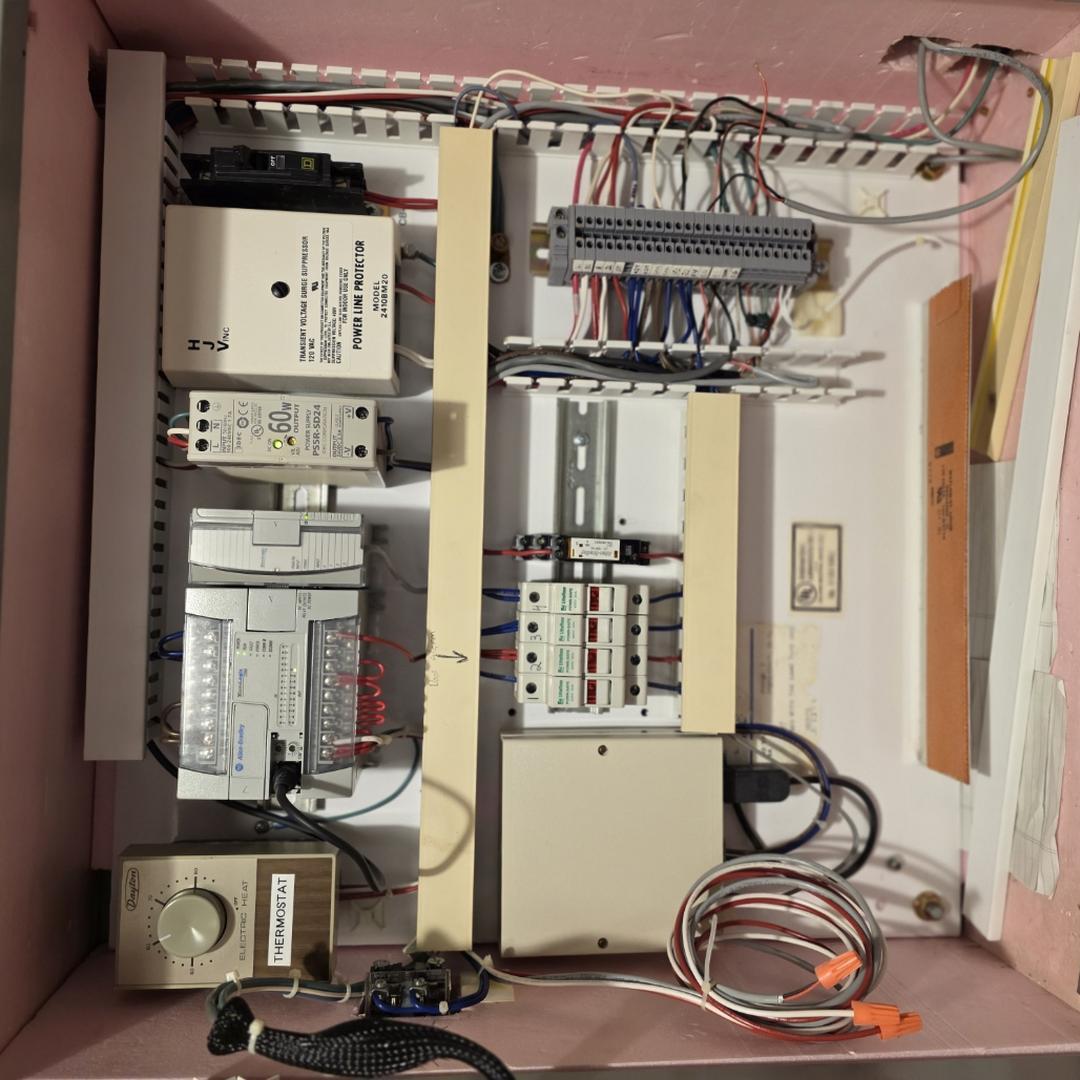

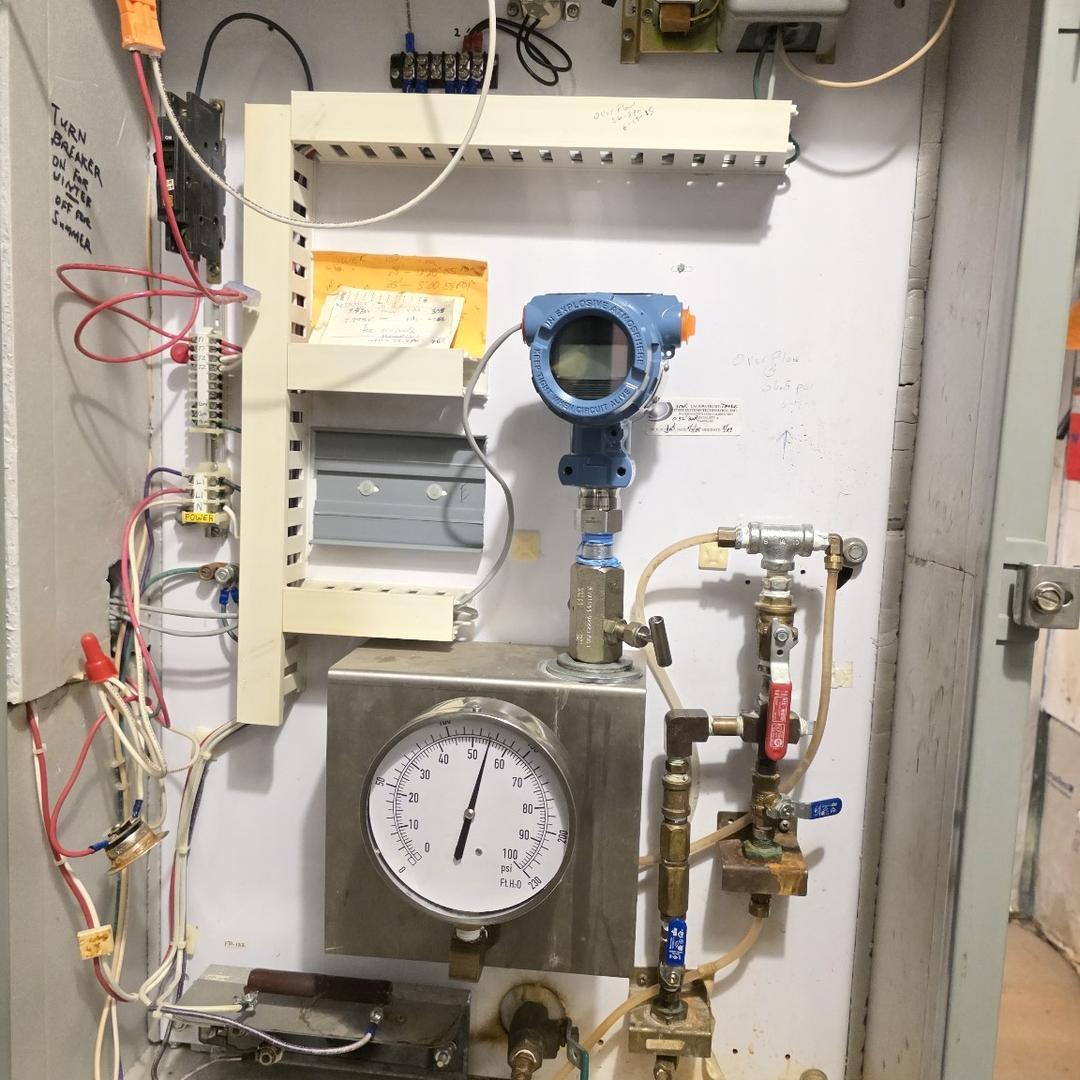

By Tuesday afternoon, we were on-site. We met the plant operator, went through the safety briefing, and made our way to the tower’s base control room where the transducer cable terminated.

The old sensor was still partially responsive, but clearly erratic. It was intermittently jumping between readings and had even flatlined at zero during the night, a major red flag. We carefully removed the old sensor, checking for moisture intrusion and connector corrosion. Sure enough, the internal cavity had signs of moisture buildup, and the seal had deteriorated.

With the replacement sensor in hand, we moved quickly:

We installed the new transducer in the same mounting bracket

Programmed the transmitter with the correct span and offset values

Verified the 4-20 mA output to ensure it matched the control system’s expectations

Ran a real-time simulation to confirm level tracking in the SCADA system

By 4:30 PM, the water tower’s level monitoring system was live again and responding flawlessly. Total turnaround: less than 36 hours from the initial phone call to full functionality.

The Bigger Lesson

This story might sound like a routine service call, but there’s an important takeaway: calibration data isn’t just a box to check — it’s a blueprint for faster, smarter response when things break.

Because we had performed a proper calibration the year before, and logged it correctly, we were able to:

Identify the failed unit quickly

Order the right part without onsite guesswork

Pre-calibrate with precision

Install and verify functionality same-day

Without that historical data, we would have had to:

Wait until we were onsite to gather the sensor’s make and model

Confirm with the manufacturer or dig through documentation to set up scaling and output ranges

Calibrate from scratch, sometimes in suboptimal field conditions

Possibly make a second trip due to configuration or part delays

That could’ve easily meant 3–4 days of downtime. Instead, it was less than 2.

The Value of Proactive Calibration

At Calibrations & Controls, we don’t just calibrate, we build technical histories for every site we touch. That means the next time something fails, we’re not starting from scratch. We’re picking up where we left off, with the data, tools, and experience to respond fast and fix it right.

To the plant operators reading this: if you’re not sure when your last calibration was, or whether your equipment documentation is still up to date, it might be time to schedule a visit.

Because when something fails (and it always does eventually), it pays to be prepared.

Want us to review your site’s instrumentation setup?

📞 Give us a call or shoot us a message — we’ll make sure you’re not flying blind when the unexpected happens.