When Baxter’s water treatment team called to report issues with their chlorine feed mag meter, they weren’t just facing a simple inconvenience—they were dealing with a critical piece of instrumentation that directly impacts chemical dosing accuracy and system compliance. Without reliable flow measurement, it’s nearly impossible to maintain proper disinfection or meet MPCA and DNR reporting standards.

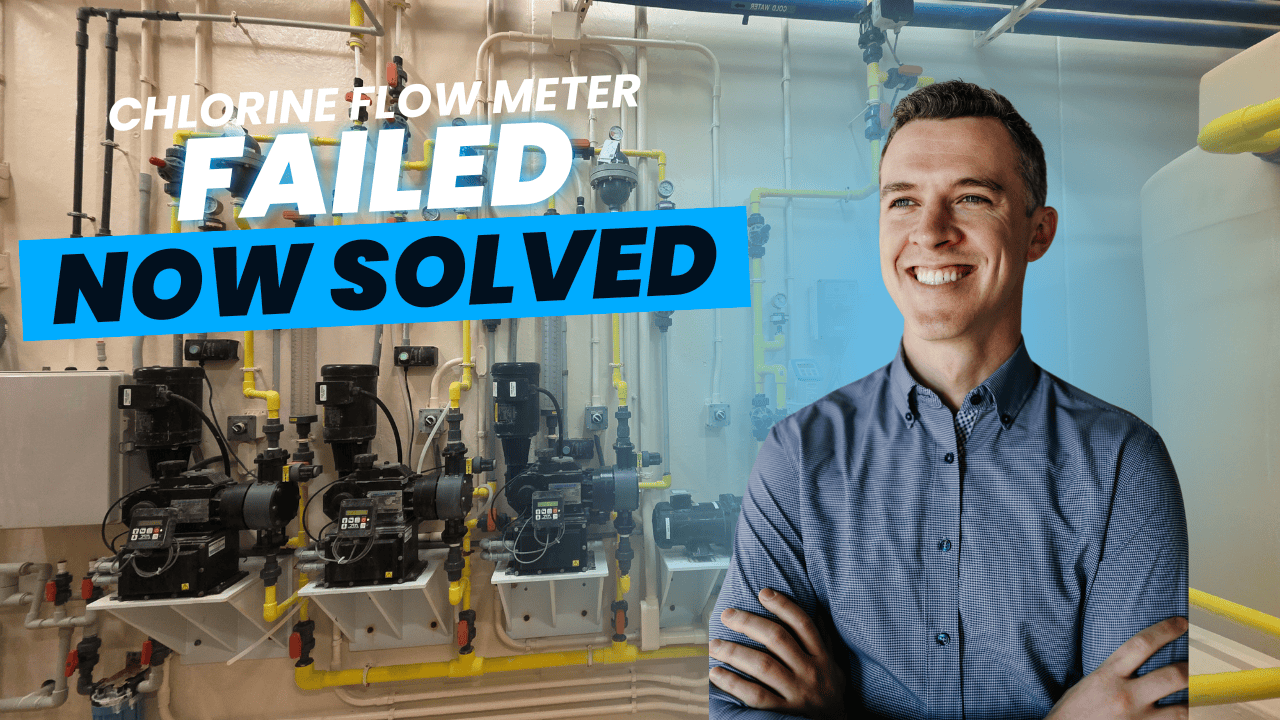

At Calibrations & Controls, we know how urgent these issues are. Within the same day, we were on the phone with their team reviewing their system requirements and making sure we specified a new mag meter that could handle the unique demands of their chlorine feed line—chemical compatibility, flow profile, pressure, and installation orientation all needed to be taken into account.

Once the correct meter was sourced and delivered, we scheduled the installation. Greg and Brad—two of our senior technicians—were assigned to handle the full scope of the project: removal, installation, commissioning, and calibration.

The Setup: A Vertical Pipe and 50 Feet of Challenge

When we arrived on site, it quickly became clear that this job wasn’t going to be a simple swap. The existing flow meter was installed vertically, with roughly 50 feet of pipe full of process fluid directly above it. And—of course—no isolation valve anywhere close.

Removing the old meter blindly would’ve meant releasing hundreds of gallons of chlorinated water into the workspace. Not only would that be a mess, it’d also pose a serious safety and environmental concern. So we had to get creative.

Controlled Drain: Timing, Precision, and a Bit of Sweat

Greg started loosening the bolts on the mag meter sensor—very slowly and carefully. By slightly cracking the sensor loose, he allowed the fluid to begin draining under control. We positioned a large funnel beneath the sensor with a flexible hose leading into a nearby discharge basin. This helped manage most of the runoff.

Still, due to the height and orientation, we knew we couldn’t catch it all. We kept a secondary catch bucket on standby for overflow, and when that first crack gave way and fluid started coming fast—we jumped into action. Brad called it “the fastest five-gallon bucket swap I’ve ever done.”

We managed to keep the area clean, safe, and well-contained. No spilled chemical, no panic. Just a little adrenaline.

Installation: Not All Mag Meters Are Built the Same

While the pipe drained, Brad started prepping the new remote-mounted transmitter while Greg cleaned up the flange faces, removed the old grounding rings, and inspected for gasket damage or pipe irregularities.

One thing a lot of people don’t realize is that mag meter installations are not one-size-fits-all. Depending on the manufacturer and the orientation of the installation (horizontal vs vertical), torque specs and grounding requirements can vary significantly. In this case, we were replacing an older unit with a newer model from Siemens, so we double-checked the manufacturer’s latest installation guidelines.

Greg installed new gaskets, a fresh set of grounding rings, and carefully torqued the bolts to spec using a calibrated torque wrench. No shortcuts.

Meanwhile, Brad had the new transmitter mounted and wired, ready for signal testing.

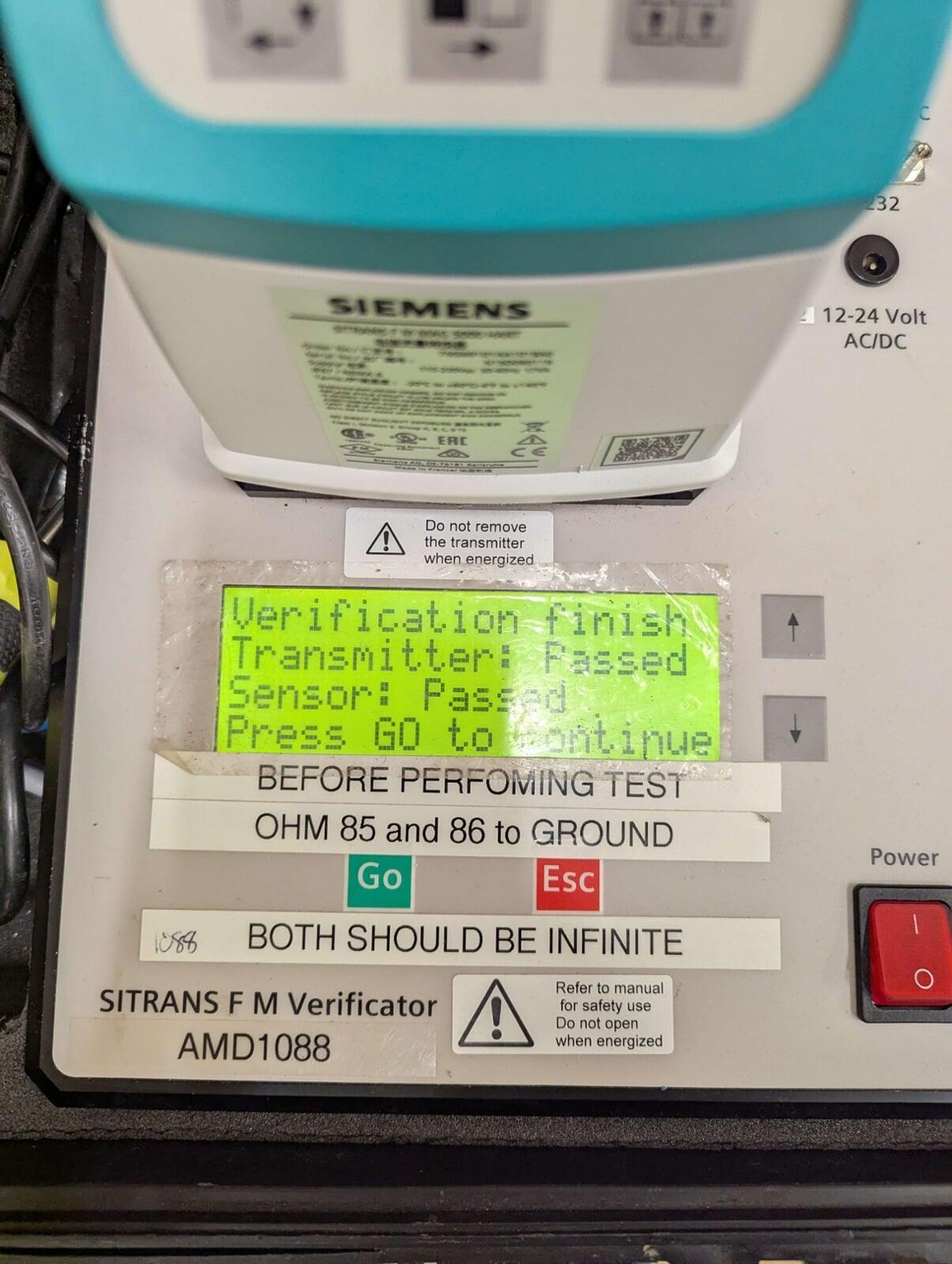

Calibration & Verification: Trust But Verify

Once everything was installed, we performed a verification using the Siemens Mag Verificator—a tool developed by the manufacturer to confirm proper operation of their magnetic flow sensors and transmitters. This step isn’t just recommended—it’s essential.

The verificator simulates magnetic fields and checks the electronics against factory calibration data. It’s one of the few ways to validate that everything is working correctly before putting the system back online.

With verification passed, we had the plant operator start up the system and run process fluid through the line. We inspected for leaks at every flange and confirmed that the meter was reading accurately and transmitting to their SCADA system as expected. Everything checked out perfectly.

Why This Matters

This job was more than just replacing a broken meter. It was a perfect example of why qualified instrumentation technicians and manufacturer-aligned procedures matter. From understanding the process constraints, to designing a controlled drain solution, to verifying the sensor post-install—we covered every angle.

The Baxter team walked away with:

A fully operational and accurate chlorine flow meter

Verified performance with a manufacturer verificator

Proper documentation for compliance

Confidence in the system moving forward

Need Help with a Flow Meter or Chemical Feed System?

Whether it’s a tricky vertical installation or a quick verification before startup, our team is trained and equipped to handle it. We work with all major brands, follow best practices, and come prepared for whatever the job throws at us.

Need a hand? We’re just a phone call away—and yes, we bring the buckets too.